Forklifts are essential tools in many industrial and warehouse settings, facilitating the movement of heavy loads and enhancing operational efficiency. However, they also pose significant safety risks if not operated correctly. One of the critical aspects of forklift safety is understanding the various warning light symbols that alert operators to potential issues. This comprehensive guide aims to illuminate the meanings of these symbols, their importance in maintaining safety, and best practices for their use.

Forklift warning lights serve as vital indicators for operators, providing real-time feedback on the machine's status. These lights can signify anything from minor issues, like low fuel levels, to critical alerts that require immediate attention. Misinterpreting or ignoring these signals can lead to accidents, equipment damage, or even injuries. Therefore, understanding what each symbol means is crucial for any forklift operator.

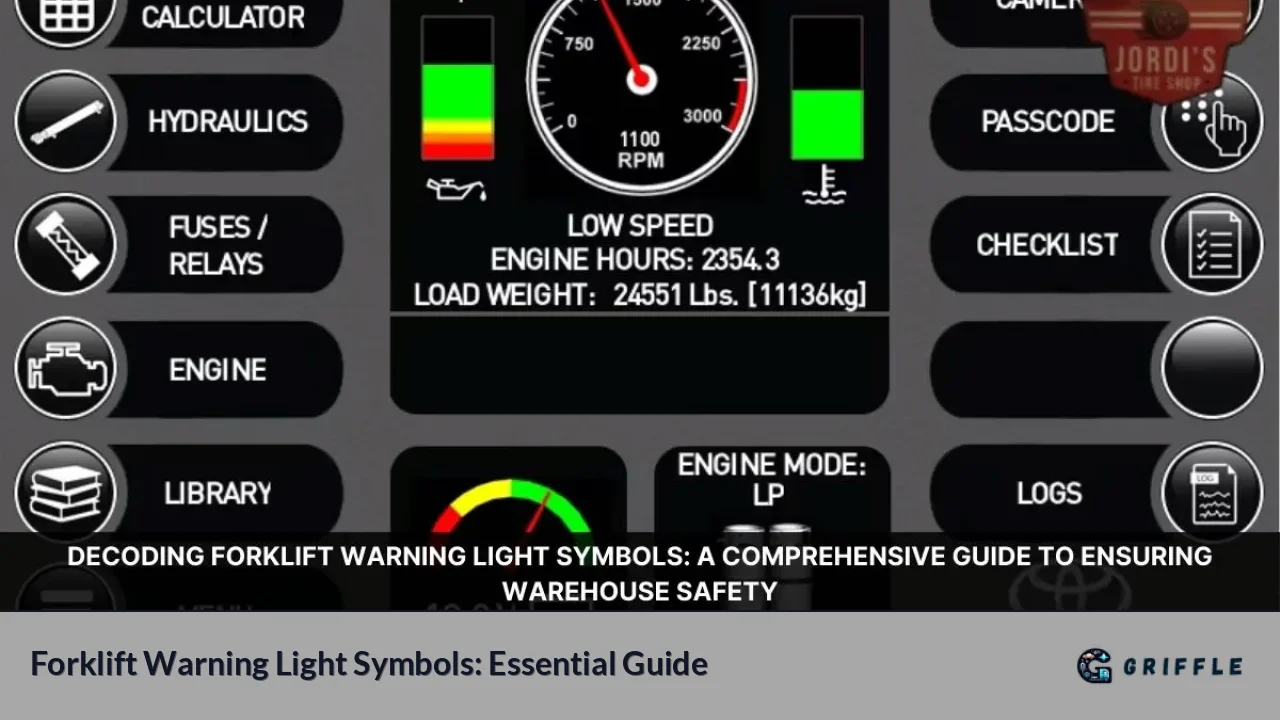

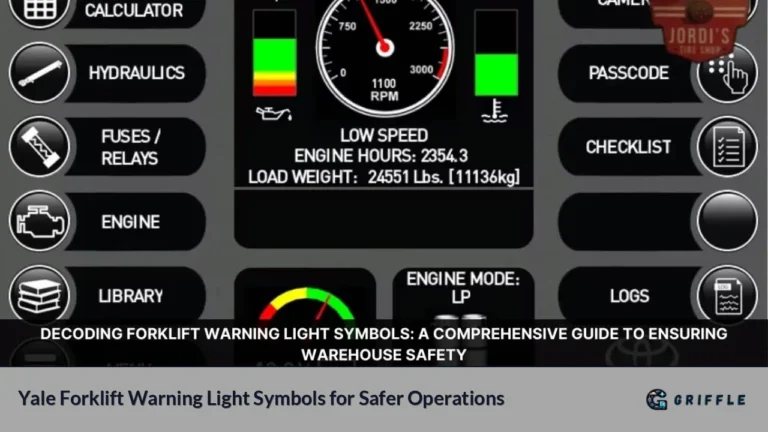

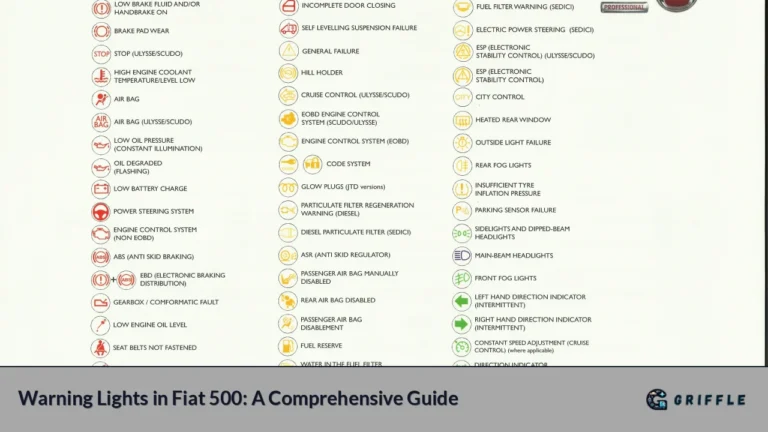

Table of Common Forklift Warning Light Symbols

| Symbol | Description | Meaning |

|---|---|---|

| Battery Warning Light | Battery Icon | Indicates low battery charge or charging system issues. |

| Oil Pressure Light | Oil Canister | Signifies low oil pressure; immediate action required. |

| Temperature Warning Light | Thermometer | Indicates engine overheating; stop operation immediately. |

| Hydraulic Oil Warning Light | Oil Can with Wavy Line | Signals low hydraulic fluid level or system issues. |

| Brake Warning Light | Exclamation Mark in Circle | Represents a problem with the braking system; check fluid levels. |

The Importance of Forklift Warning Lights

Understanding forklift warning lights is not just about compliance; it’s about fostering a culture of safety within the workplace. Here are some key reasons why these symbols are crucial:

- Prevent Accidents: Forklift accidents can lead to severe injuries or fatalities. Recognizing warning lights helps operators take preventive measures before a situation escalates.

- Maintenance Awareness: Warning lights often indicate maintenance needs. Addressing these alerts promptly can prevent costly repairs and extend the lifespan of the equipment.

- Operational Efficiency: By ensuring that forklifts are functioning correctly, businesses can maintain productivity levels without unnecessary downtime caused by equipment failures.

Types of Forklift Warning Lights

Forklifts are equipped with various types of warning lights that serve different functions:

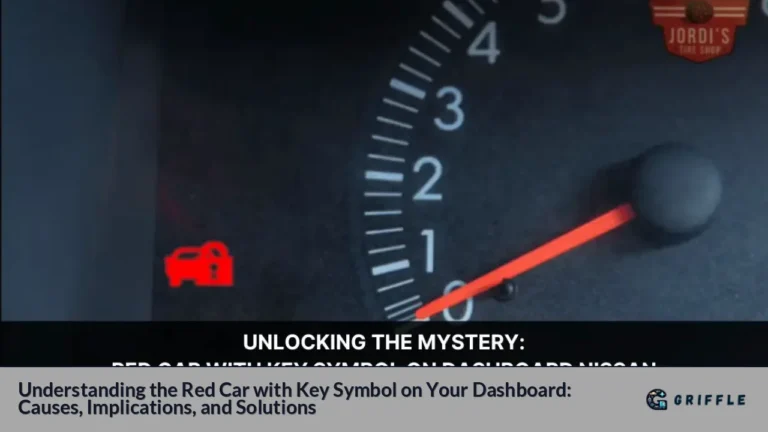

- Dashboard Warning Lights: These lights are located on the forklift's dashboard and provide information about the machine's operational status.

- Safety Lights: These include strobe lights and colored LEDs that signal the presence of a forklift to pedestrians and other operators.

- Directional Lights: Used to indicate the direction in which the forklift is moving, enhancing visibility in busy environments.

Common Forklift Warning Light Symbols Explained

Battery Warning Light

The battery warning light typically appears as a battery icon. When illuminated, it indicates that the forklift's battery charge is low or there may be an issue with the charging system. Operators should check battery connections and consult a technician if necessary.

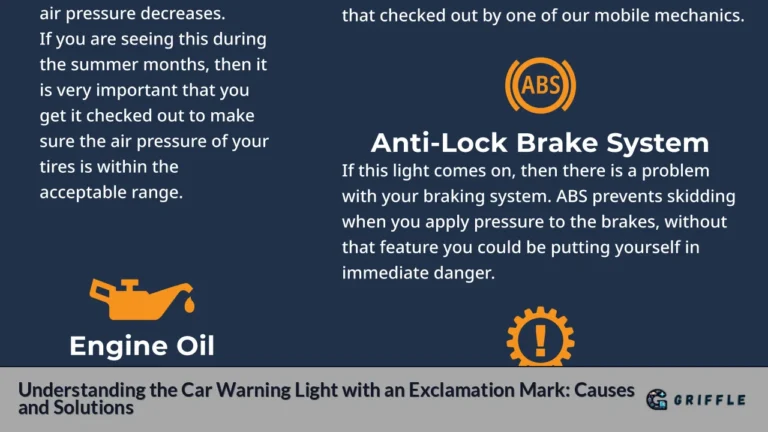

Oil Pressure Light

Represented by an oil canister symbol, this light signifies low oil pressure within the engine. If this light remains on after starting, operators should stop the engine immediately and check the oil level.

Temperature Warning Light

A thermometer submerged in liquid symbolizes this light. It warns operators that the engine is overheating, necessitating an immediate shutdown to prevent damage.

Hydraulic Oil Warning Light

This light appears as an oil can with a wavy line beneath it, indicating low hydraulic fluid levels or potential issues within the hydraulic system. Operators should check fluid levels and address any leaks promptly.

Brake Warning Light

An exclamation mark inside a circle signifies problems with the braking system. This could result from low brake fluid or worn-out brake pads and requires immediate attention to ensure safe operation.

Best Practices for Using Forklift Warning Lights

To maximize safety and efficiency in forklift operations, consider implementing these best practices:

- Regular Training: Ensure all operators are trained to recognize and respond to warning lights appropriately.

- Daily Inspections: Conduct daily checks on all warning lights before operating forklifts to ensure they are functioning correctly.

- Maintenance Protocols: Establish protocols for addressing warning signals promptly to prevent equipment failure and maintain safety standards.

- Consistent Communication: Foster an environment where operators feel comfortable reporting issues without fear of repercussions.

Conclusion

Understanding forklift warning light symbols is essential for maintaining safety in industrial environments. By recognizing these symbols and responding appropriately, operators can significantly reduce the risk of accidents and ensure efficient operations.

Investing time in training and creating awareness around these symbols not only protects employees but also enhances overall workplace productivity. As forklifts remain integral to many industries, prioritizing safety through knowledge of warning lights should be a fundamental part of operational protocols.

FAQs

- What does a flashing red light on a forklift mean?

A flashing red light typically indicates a critical issue that requires immediate attention from a qualified technician. - How often should I check my forklift's warning lights?

It's advisable to check all warning lights daily before operation to ensure they function correctly. - Can I ignore a yellow warning light?

No, yellow warning lights indicate caution; while they may not require immediate action, they should be addressed as soon as possible. - What should I do if multiple warning lights are on?

If multiple warning lights illuminate simultaneously, stop using the forklift immediately and consult maintenance personnel. - Are there specific regulations regarding forklift lighting?

Yes, OSHA regulations require certain lighting configurations based on visibility conditions; always ensure compliance with local regulations.