Forklifts are essential in various industries, especially in warehouses and construction sites, where they facilitate the movement of heavy loads. However, operating a forklift comes with inherent risks. One of the critical aspects of ensuring safety during forklift operation is understanding the warning light symbols displayed on the dashboard. This article provides a comprehensive overview of forklift warning light symbols, their meanings, and the importance of adhering to these signals for safe operations.

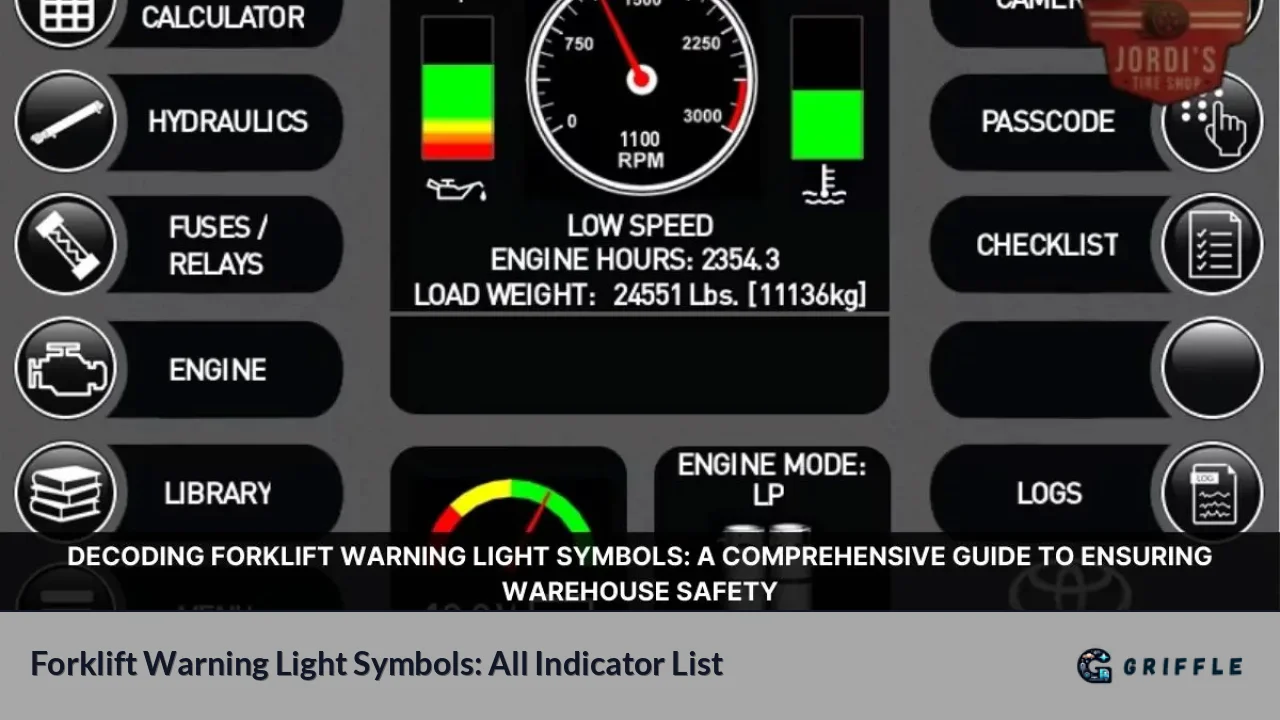

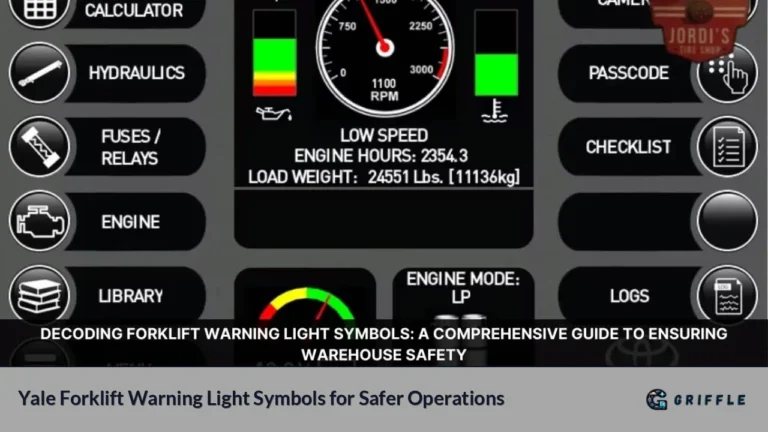

Forklifts are powerful machines that require skilled operators to ensure safe handling and transportation of materials. The dashboard warning lights on a forklift serve as vital indicators of the machine's operational status and potential issues that could arise during use. Understanding these symbols is crucial for operators to prevent accidents and ensure the safety of both personnel and equipment.

The Significance of Warning Lights

Warning lights are not merely decorative features; they play a crucial role in alerting operators to potential hazards or malfunctions. Ignoring these signals can lead to severe accidents, equipment damage, or even fatalities.

Importance of Forklift Warning Lights

Forklift warning lights serve several essential functions:

- Enhanced Visibility: They make forklifts more visible to pedestrians and other operators, especially in low-light conditions.

- Accident Prevention: By alerting operators to potential issues, warning lights help prevent accidents before they occur.

- Compliance with Regulations: Many workplaces are required by safety regulations to have functioning warning lights on forklifts.

- Increased Operator Confidence: Knowing that the warning systems are in place allows operators to focus on their tasks without unnecessary distractions.

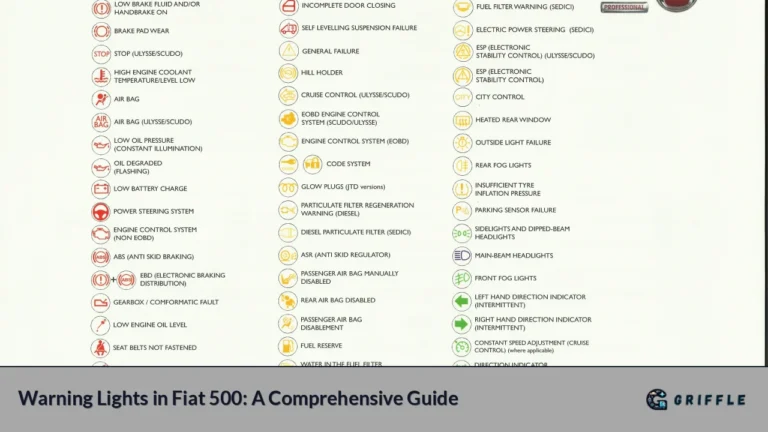

Common Forklift Warning Light Symbols and Their Meanings

Understanding the various symbols on a forklift's dashboard is essential for safe operation. Below is a detailed overview of common warning light symbols and their meanings:

| Symbol | Meaning |

|---|---|

| Battery Icon | Battery Warning Light: Indicates low battery charge or charging system issues. Check connections or consult a technician if this light remains on. |

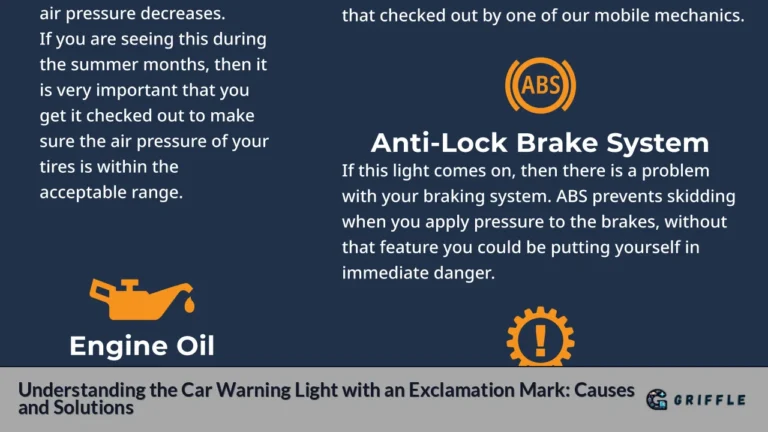

| Oil Can Icon | Engine Oil Pressure Light: Signals low oil pressure; immediate action is required to prevent engine damage. |

| Thermometer Icon | Temperature Warning Light: Indicates engine overheating; stop the engine and check coolant levels immediately. |

| Hydraulic Fluid Icon | Hydraulic Oil Warning Light: Warns of low hydraulic fluid levels or system issues that could affect lifting capabilities. |

| Brake Icon | Brake Warning Light: Indicates problems with the braking system, such as low brake fluid or worn-out pads. |

| Tilt Icon | Tilt Warning Light: Alerts the operator when the mast tilt angle exceeds safe limits; adjust loads or mast accordingly. |

| Seatbelt Icon | Seatbelt Warning Light: Reminds operators to wear seatbelts for safety before operating the forklift. |

| Air Filter Icon | Air Filter Warning Light: Indicates a clogged air filter that may need replacement for optimal engine performance. |

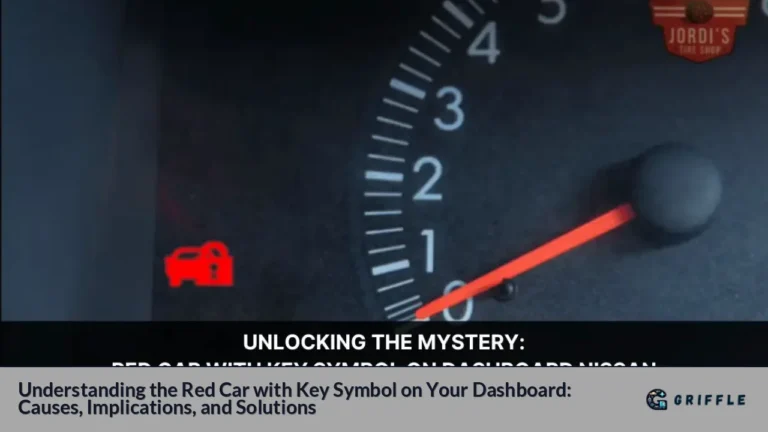

| Check Engine Icon | Check Engine Light: A general indicator that there is a malfunction within the engine management system; diagnostic tools can help identify specific issues. |

| Transmission Icon | Transmission Warning Light: Suggests problems with the transmission system that require immediate attention. |

The Role of Diagnostic Tools in Forklift Safety

With advancements in technology, diagnostic tools have become indispensable for maintaining forklift safety and efficiency. These tools can quickly identify issues indicated by warning lights, allowing for prompt repairs and minimizing downtime.

Benefits of Using Diagnostic Tools

- Accurate Problem Identification: Diagnostic tools can pinpoint specific malfunctions based on error codes, reducing guesswork during repairs.

- Time Efficiency: Quick diagnostics save time for both operators and maintenance personnel, ensuring forklifts are back in operation swiftly.

- Preventive Maintenance: Regular use of diagnostic tools helps identify potential problems before they escalate into serious issues.

Conclusion

Understanding forklift warning light symbols is crucial for ensuring safe operations in environments where forklifts are used. Operators must be vigilant about these indicators and take immediate action when any warning light illuminates on their dashboard. Additionally, integrating diagnostic tools into maintenance routines can significantly enhance safety and efficiency in forklift operations.

By prioritizing safety through knowledge and proper maintenance practices, companies can create a safer working environment for all employees involved in forklift operations.

FAQs

- What does a red warning light mean on a forklift?

A red warning light typically indicates a serious issue that requires immediate attention, such as brake failure or an overloaded condition. - How often should I check my forklift's warning lights?

Operators should perform daily checks before use to ensure all warning lights are functioning correctly. - What should I do if a warning light comes on while operating?

Immediately stop the forklift and assess the situation based on the specific warning light illuminated. - Are there specific regulations regarding forklift warning lights?

Yes, OSHA regulations require certain lighting configurations for forklifts to ensure safety in various work environments. - Can I ignore a yellow warning light?

No, yellow lights indicate caution; while they may not require immediate action, they should be addressed promptly to prevent further issues.