Forklifts are essential tools in various industries, facilitating the movement of goods and materials. However, their operation comes with inherent risks, particularly in busy environments where pedestrians and other vehicles are present. To enhance safety, Linde forklifts are equipped with a variety of warning light symbols that communicate critical information to operators and bystanders. This article delves into the significance of these warning light symbols, common issues faced by users, and effective solutions to enhance safety in the workplace.

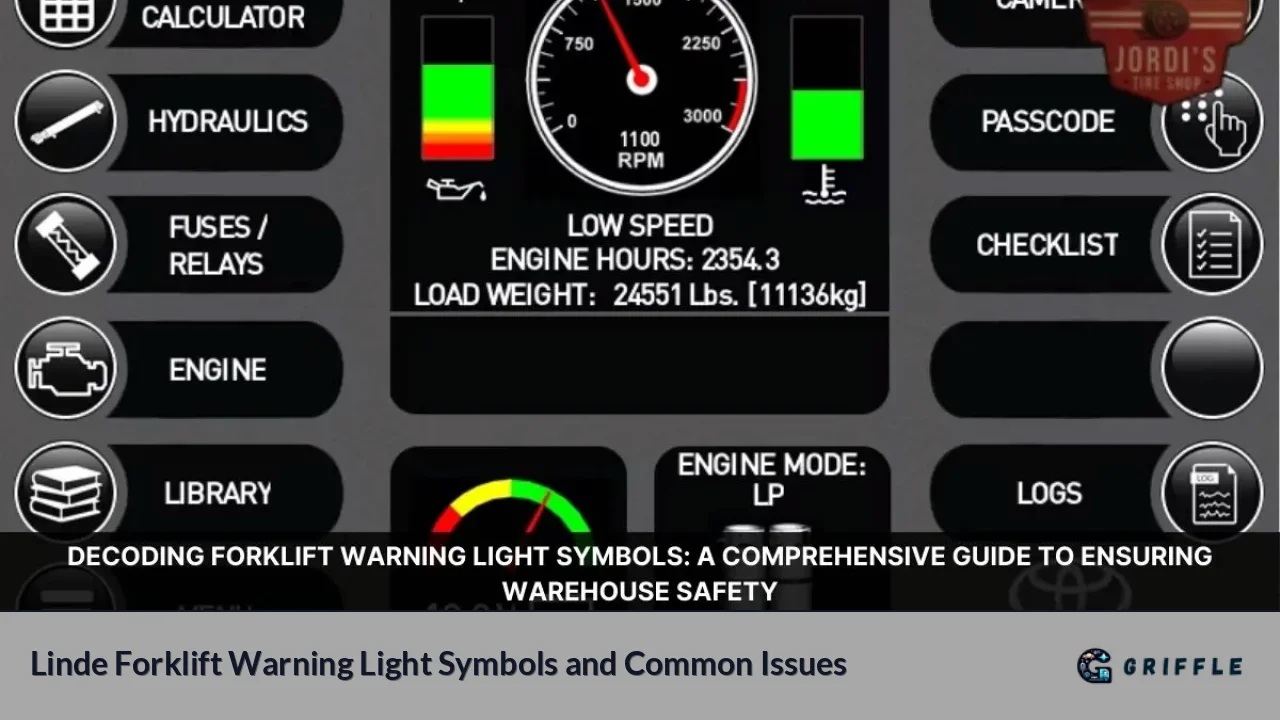

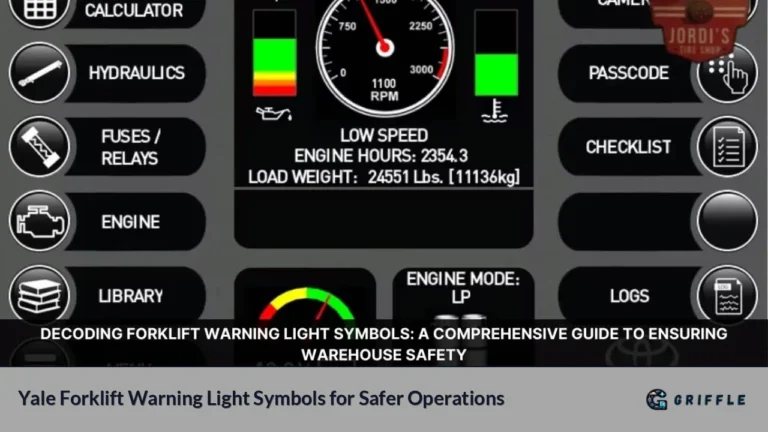

Linde forklifts utilize an array of warning light symbols to convey important operational statuses and alerts. These symbols serve as visual cues for operators, helping them navigate potential hazards and ensuring safe operation. Despite their importance, many users struggle to understand these symbols, leading to misinterpretation and potentially dangerous situations.

This guide aims to clarify the meanings behind Linde forklift warning light symbols, address common user concerns, and provide actionable solutions for improving safety protocols in workplaces that utilize these machines.

Common Issues with Linde Forklift Warning Light Symbols

Misinterpretation of Symbols

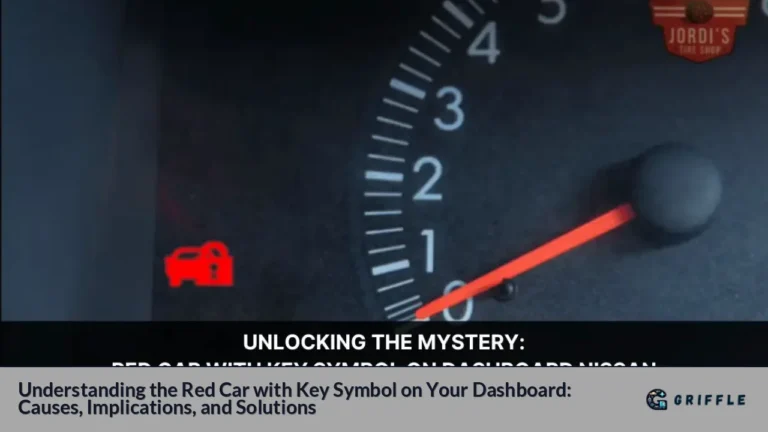

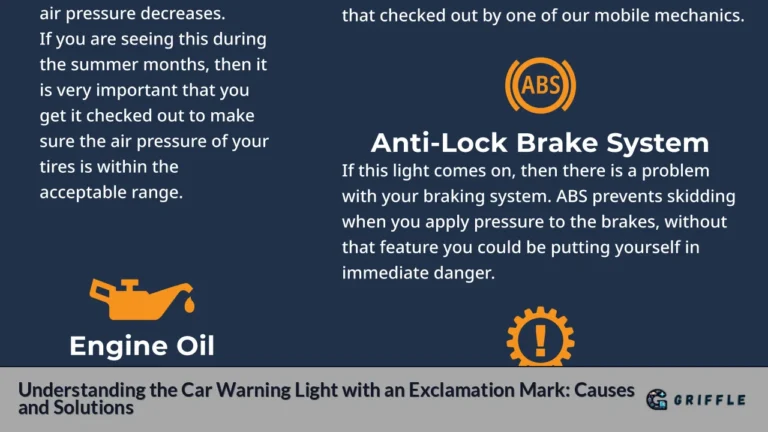

One of the most significant challenges faced by operators is the misinterpretation of warning light symbols. Many users are not adequately trained to recognize these symbols, leading to confusion during operation. For instance, a flashing battery warning light might be mistaken for a general alert rather than an indication of low battery power.

Lack of Training

Inadequate training on the meaning and importance of warning lights can lead to serious safety hazards. Operators who do not understand what each symbol represents may fail to take necessary actions in response to warnings, increasing the risk of accidents.

Equipment Malfunctions

Sometimes, warning lights can illuminate due to equipment malfunctions that do not necessarily correlate with actual operational issues. For example, a faulty sensor might trigger a warning light erroneously, causing unnecessary concern among operators.

Solutions to Enhance Safety

Comprehensive Training Programs

To address the issue of misinterpretation and lack of knowledge regarding warning lights, companies should implement comprehensive training programs for all forklift operators. These programs should cover:

- Identification of Warning Symbols: Operators should be trained to recognize each symbol and understand its implications.

- Response Protocols: Clear guidelines should be established for how operators should respond when specific warning lights activate.

- Regular Refresher Courses: Ongoing training sessions can help reinforce knowledge and keep safety protocols fresh in operators' minds.

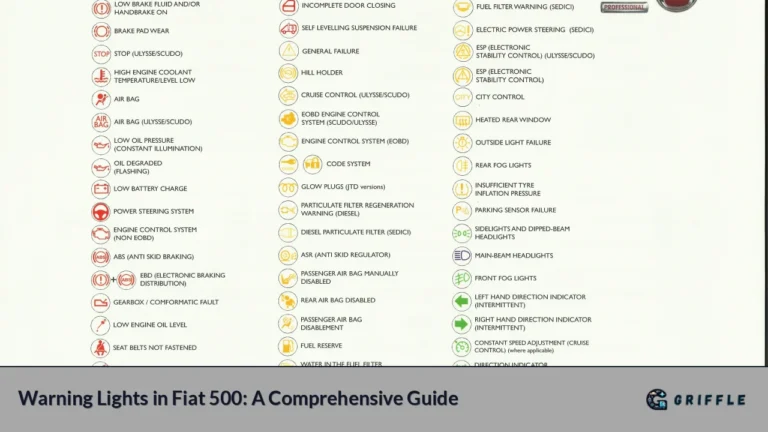

Visual Aids and Reference Materials

Providing visual aids such as posters or digital displays that outline the meanings of various warning light symbols can significantly aid operator understanding. These materials should be placed in visible areas near workstations or within operator cabins for quick reference.

Implementing Technology Solutions

Advancements in technology can also enhance safety measures related to forklift operations. For instance:

- Real-time Monitoring Systems: Implementing systems that monitor forklift performance in real-time can help identify issues before they trigger warning lights.

- Mobile Applications: Developing mobile applications that provide instant access to information about warning lights can empower operators with knowledge at their fingertips.

Regular Maintenance Checks

Conducting regular maintenance checks on forklifts can help prevent malfunction-related warnings. Routine inspections should include:

- Sensor Calibration: Ensuring sensors are calibrated correctly reduces the likelihood of false alarms.

- Battery Health Checks: Regularly checking battery health can prevent low charge warnings from occurring unexpectedly.

Conclusion

Understanding Linde forklift warning light symbols is crucial for ensuring safe operations in environments where these machines are used. By addressing common issues such as misinterpretation and lack of training, companies can significantly enhance workplace safety.

Implementing comprehensive training programs, utilizing visual aids, adopting technology solutions, and conducting regular maintenance checks are all effective strategies that can lead to safer forklift operations. Ultimately, fostering a culture of safety awareness among operators will not only reduce accidents but also improve overall operational efficiency.

FAQs

- What does a flashing battery light indicate?

A flashing battery light typically indicates low battery power or charging issues. - How can I learn more about Linde forklift warning lights?

Operators can refer to training manuals or attend training sessions provided by their employer. - What should I do if a warning light comes on while operating?

Immediately assess the situation according to your training; consult your manual if unsure. - Are there any visual aids available for understanding these symbols?

Yes, many companies provide posters or digital resources outlining the meanings of various warning lights. - How often should I check my forklift's warning systems?

Regular maintenance checks should be conducted as part of your company's safety protocols.