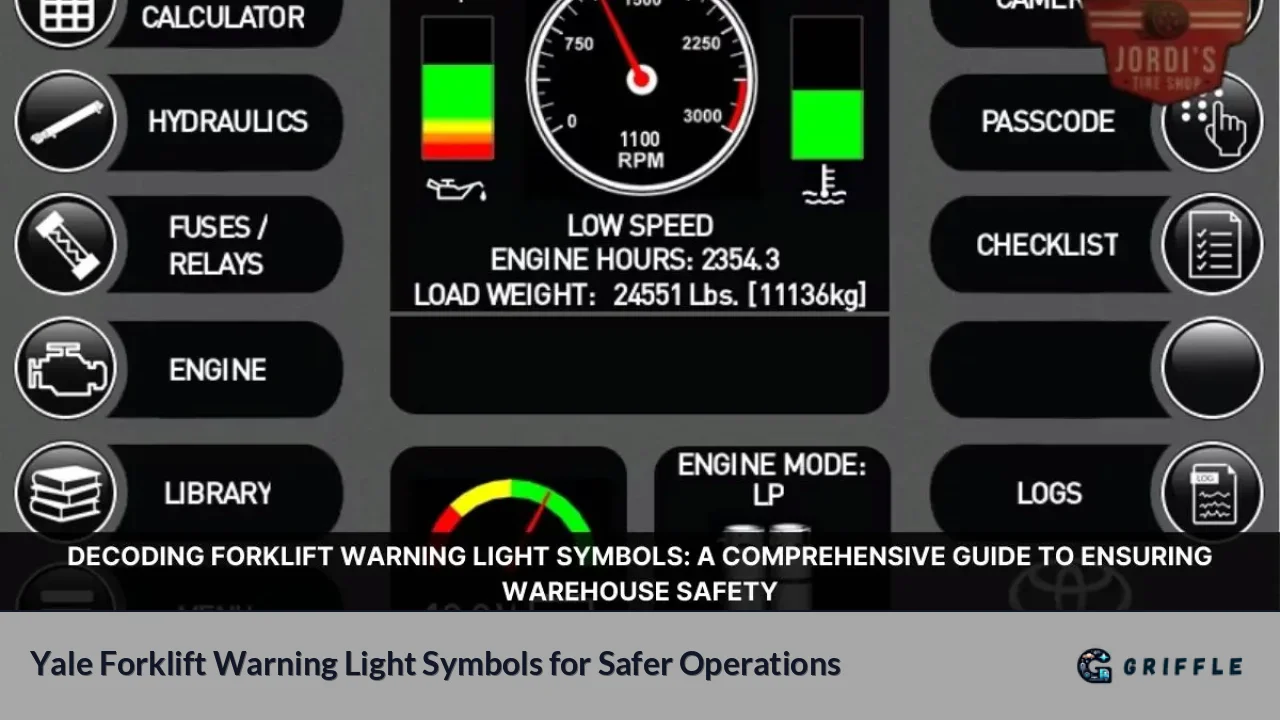

Forklifts are essential tools in various industries, facilitating the movement of heavy materials with ease. However, like all machinery, they come with their own set of challenges. One of the most critical aspects of operating a forklift safely is understanding the warning light symbols displayed on the dashboard. This article delves into Yale forklift warning light symbols, their meanings, and how operators can effectively respond to these warnings to ensure safety and efficiency in operations.

Forklift operators often encounter various warning lights while using their machines. These lights serve as indicators of potential issues that could affect the forklift's performance or safety. Understanding these symbols is crucial for preventing accidents and ensuring the longevity of the equipment.

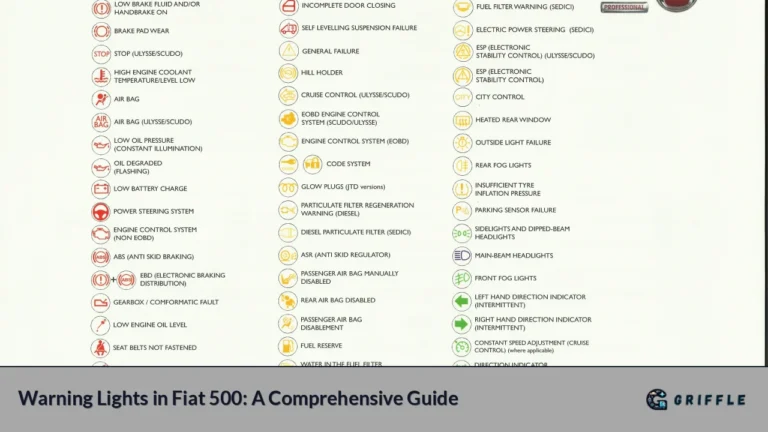

The following table summarizes common Yale forklift warning light symbols and their meanings:

| Warning Light Symbol | Meaning |

|---|---|

| Battery Warning | Indicates low battery charge or charging system issues. |

| Engine Oil Pressure | Signifies low oil pressure; immediate action is required. |

| Temperature Warning | Indicates engine overheating; turn off the engine immediately. |

| Transmission Warning | Suggests a problem with the transmission system. |

| Brake Warning | Represents an issue with the braking system. |

| Seatbelt Warning | Reminds the operator to buckle up before operating the forklift. |

Common Yale Forklift Warning Lights and Their Meanings

Battery Warning Light

The battery warning light typically appears as a battery icon. This light indicates that the forklift's battery charge is low or that there is an issue with the charging system. Operators should check battery connections and consider replacing the battery if necessary.

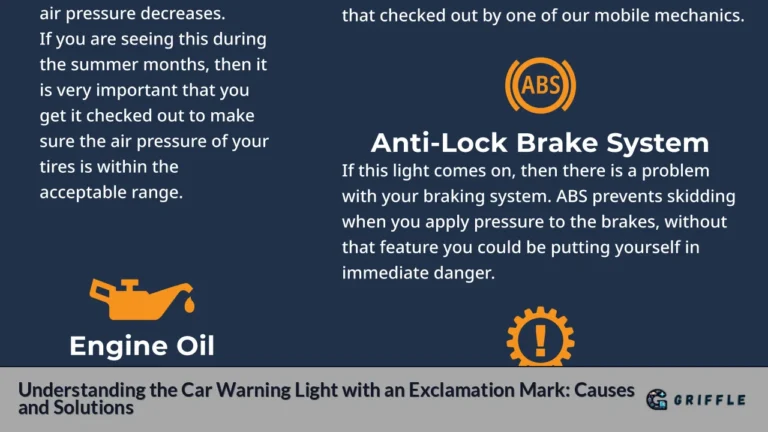

Engine Oil Pressure Light

This symbol resembles an oil canister and signifies low oil pressure within the engine. If this light remains illuminated after starting, operators must stop the engine, check the oil level, and consult a technician if needed to prevent severe engine damage.

Temperature Warning Light

Represented by a thermometer submerged in liquid, this warning indicates that the engine is overheating. Operators should turn off the engine immediately, allow it to cool down, and check coolant levels. If levels are adequate, further investigation into radiator or thermostat issues may be required.

Transmission Warning Light

This symbol often looks like a gear with an exclamation mark. It suggests a problem within the transmission system, which could involve fluid levels, gears, or other components. Operators should consult a technician for diagnosis and repair.

Brake Warning Light

The brake warning light usually appears as an exclamation mark inside a circle. This indicates potential issues with the braking system, such as low brake fluid or worn-out brake pads. Prompt attention is essential for maintaining safety.

Seatbelt Warning Light

This symbol shows a seated figure with a seatbelt across its lap. It serves as a reminder for operators to fasten their seatbelts before operating the forklift, emphasizing safety during operation.

Importance of Understanding Warning Lights

Understanding warning lights on Yale forklifts is vital for several reasons:

- Safety: Recognizing warning signals helps prevent accidents and injuries by ensuring that operators take necessary actions promptly.

- Equipment Longevity: Addressing issues indicated by warning lights can prevent further damage to machinery, thus extending its lifespan.

- Operational Efficiency: Timely responses to warnings can minimize downtime and maintain productivity in warehouse operations.

Common Issues Indicated by Warning Lights

Forklift operators may face several common issues indicated by warning lights:

- Low Fluid Levels: Many warning lights relate to low fluid levels (oil, hydraulic fluid, coolant). Regular checks are essential to avoid operational failures.

- Electrical Problems: Battery-related warnings often indicate electrical issues that could lead to operational failures if not addressed promptly.

- Mechanical Failures: Lights indicating problems with brakes or transmission often signify underlying mechanical failures that require immediate attention.

Best Practices for Responding to Warning Lights

To effectively respond to warning lights on Yale forklifts:

- Know Your Symbols: Familiarize yourself with all dashboard symbols specific to your forklift model.

- Regular Inspections: Conduct pre-shift inspections to identify potential issues before they escalate.

- Immediate Action: If a warning light illuminates during operation, take immediate action according to your training and operational guidelines.

- Consult Manuals: Refer to your operator’s manual for detailed information about specific warning lights and recommended actions.

- Seek Professional Help: When in doubt or when serious warnings appear, consult a certified technician for diagnosis and repair.

Conclusion

Understanding Yale forklift warning light symbols is crucial for maintaining safety and efficiency in material handling operations. By recognizing these symbols and responding appropriately, operators can prevent accidents, extend equipment life, and ensure smooth operations in their workplaces. Continuous training and adherence to safety protocols are essential components of effective forklift operation.

FAQs

- What does the battery warning light mean?

The battery warning light indicates that the forklift's battery charge is low or there are issues with the charging system. - How should I respond if my temperature warning light comes on?

If this light illuminates, turn off the engine immediately and check coolant levels after allowing it to cool down. - What does it mean if my brake warning light is illuminated?

This light signifies potential problems with the braking system that need immediate attention. - Why is it important to understand warning lights?

Understanding these lights helps prevent accidents and ensures timely maintenance of equipment. - What should I do if I see multiple warning lights at once?

If multiple lights illuminate simultaneously, stop operation immediately and consult a technician for diagnosis.